Ferobide hard facing in Australia

Our Services

We can apply our brand of hardfacing to components you have, or we can source, hardface, and deliver the components you need. Whether it be for farming, earthmoving or any other high wear environment.

Our goal at Engaged Hardfacing & Wear Solutions is to not only apply hardfacing, but to develop hardfacing and wear solutions which will extend maintenance periods and reduce downtime, using a combination of available technologies.

What is Ferobide?

FEROBIDE is an innovative tungsten carbide composite material that combines a high level of wear resistance and toughness with the ease and reliability of a weldable material.

The unique features of Ferobide closes the gap between conventional tungsten carbide which requires brazing and weldable materials which have a significant lower wear performance. Ferobide is one of the world’s hardest weldable materials.

Ferobide is ideal in situations where brazing is not an option and for applications involving sliding wear. Ferobide has found its use in critical applications in several different industries such as agriculture, separation, mining, mixing, mineral processing and road maintenance.

Ferobide in Australia

To prove the quality of Ferobide tiles, we developed cane harvester base cutter discs to be used as trials to gauge the performance of Ferobide tungsten carbide tiles against traditional hard facing, in a high wear/high impact environment in varying soil types. Initial results showed exciting promise in the product and are consistent with results being seen in overseas trials, both in terms of wear and also application and repair-ability.

"Ferobide" vs "Abrasocord 43" - Cane Harvester base cutter trial - RESULTS

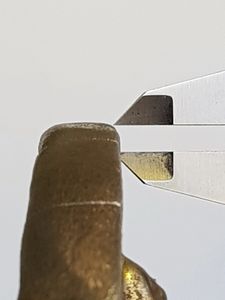

Original 'Ferobide' tile thickness of 6mm was used of the perimeter of the trial base cutters. Image shows less than 2mm of wear on the underside edge of the base cutter perimeter tiles

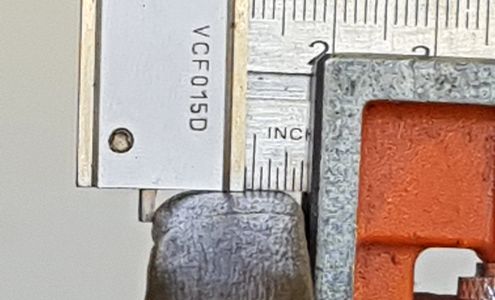

As the base cutters are pitched, the top side (leading edge) will wear more than the underside (trailing edge). This image shows the difference in wear between leading and trailing edges. Just over 2mm of additional wear to the leading edge of the perimeter tiles. Results show a total of 3.5mm of wear in the worst instance, compared to over 10mm in total wear of the Abrasocord 43 used in these trials.

This image shows the difference if wear between the Abrasocord 43 section of the perimeter in relation to the 'Ferobide'

When the base cutter was pulled from service, the second application of Abrasocord 43 had worn an additional 4-5mm. Total wear of over 10mm as opposed to 3.5mm of wear for the one application of 'Ferobide'

Ferobide exibits a resistance to dry abrasion 8 times better than 500HB hardened steels

Ferobide exibits a resistance to dry abrasion 4-5 times better than chromium-rich hardface overlay plates

Ferobide exibits a resistance to dry abrasion 3 times better than white cast iron (chromium carbide)

Ferobide exibits a resistance to dry abrasion 2 times better than 97% alumina ceramic

Ferobide exibits a resistance to wet abrasion 1.5 times better than pure tungsten carbide

Frequently Asked Questions

Please reach us at admin@engagedservicesnq.com.au if you cannot find an answer to your question.

It is very easy and quick to weld Ferobide.

When welding Ferobide, keep heat input to a minimum, and use standard MIG / MMA methods. Clamp Ferobide in place, otherwise use a single tack per tile. To guarantee the best results, please see our quick welding instructions here

When used for the correct applications, Ferobide users can achieve a much greater working life and performance from wearing metal parts. As well as increased service life, Ferobide also helps to reduce downtime and save time & money.

Ferobide can be used on a wide range of different machines and ground-engaging tools.

It is ideal to combat sliding wear, to prevent thinning or “washing” and is well suited for situations where brazing is not an option and hardfacing is too slow. Ferobide is typically used on seed drills, subsoilers, cultivators, ploughs, muck spreaders, root harvesters, sugar cane harvesters, buckets, mowers, augers, and scrapers.

Ferobide is the most durable welded material readily available on the market and has up to 10x performance versus hardfacing, and up to 6x performance versus chocky blocks. Brazed pure tungsten has a slightly better wear resistance than Ferobide and while Ferobide is comparable to brazed carbide, Ferobide is slightly less durable. Brazed carbide is the best option for leading edges.

Ferobide in 'Real World' sliding wear application

'Control'

'Ferobide'

'Ferobide'

Image showing the usual wear of the chain guides. Wear was almost right through the 6mm thick wear strip in this instance. With this amount of wear compounded by the number of bends in this particular application, the chain was fully adjusted throughout the cane season and links had to be removed to keep the chains tensioned properly.

'Ferobide'

'Ferobide'

'Ferobide'

This image shows 'Ferobide' application to the same bend areas as the control. The amount of wear on the bends in this application proved almost immeasurable.

Both the 'Control' haul out bin and 'Ferobide' bin had all wear strips replaced at the start of the season. Both bins were used simultaneously by the same contractor throughout the season.

Contact us regarding how 'Ferobide' will reduce your sliding wear issues

Click on the button to contact us to discuss in depth the application and results of this trial. Including fabrication photos of the 'Ferobide' wear bends and initial application. Also discuss what these results mean to the future of wear bends in the sugar cane harvesting process.

Proactive Maintenance

Plan to Succeed

If you have new equipment or just replaced that 'sacrificial' item on your machinery, extra investment in the initial cost will bring long term results in reduced downtime and the cost of replacements.

In-Service Benefits

When you have planned to succeed and realise that when your maintenance period has come around and you don't have to replace wear parts as previously, you will know that you have made a sound investment.

Photo gallery - Ferobide application to rotary hoe skid plate and gear cover

Gear cover was worn through. Re-built the cover and decided to apply Ferobide to improve service life.

Copyright © 2025 Engaged Services NQ Pty Ltd - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.